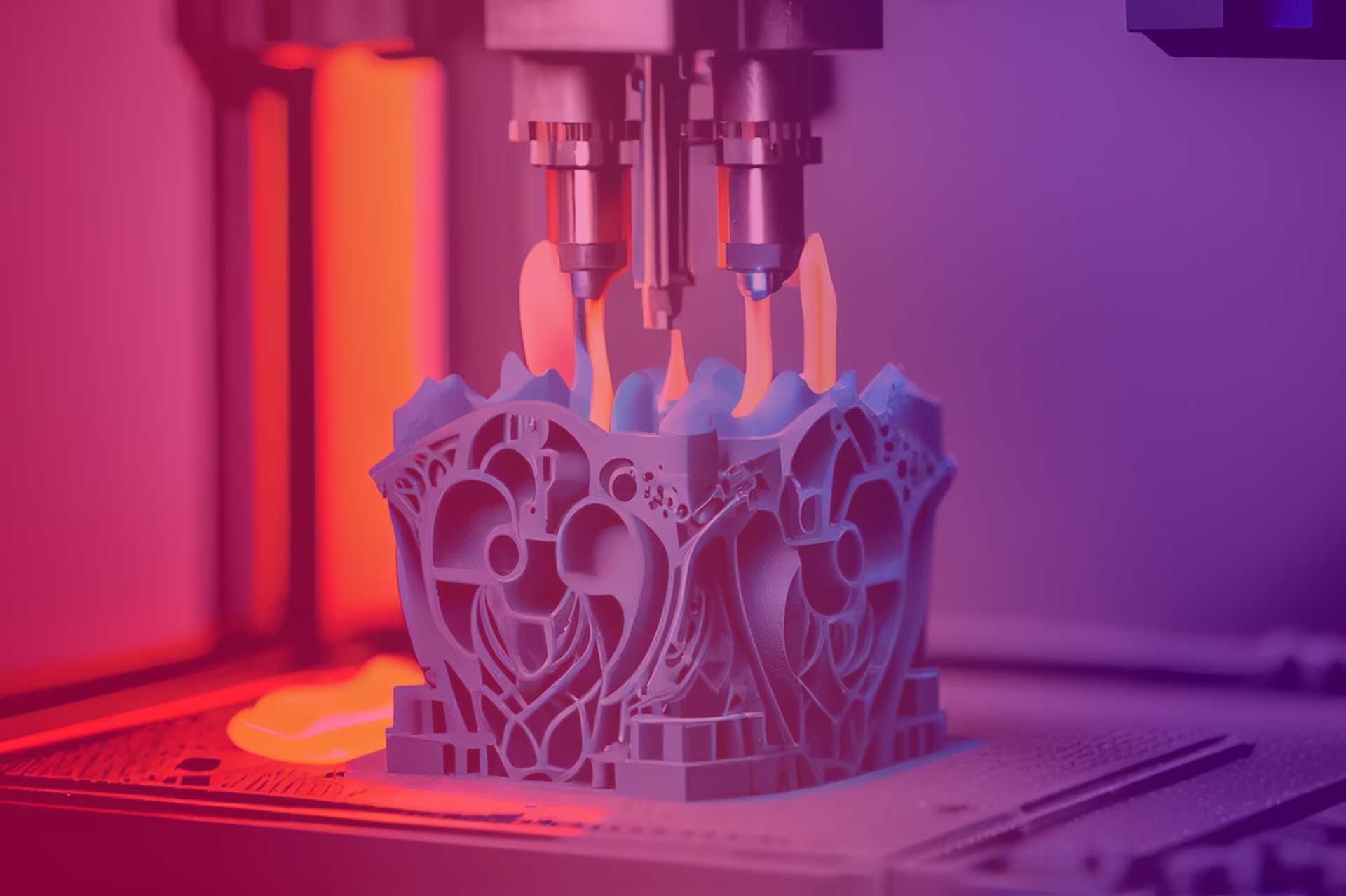

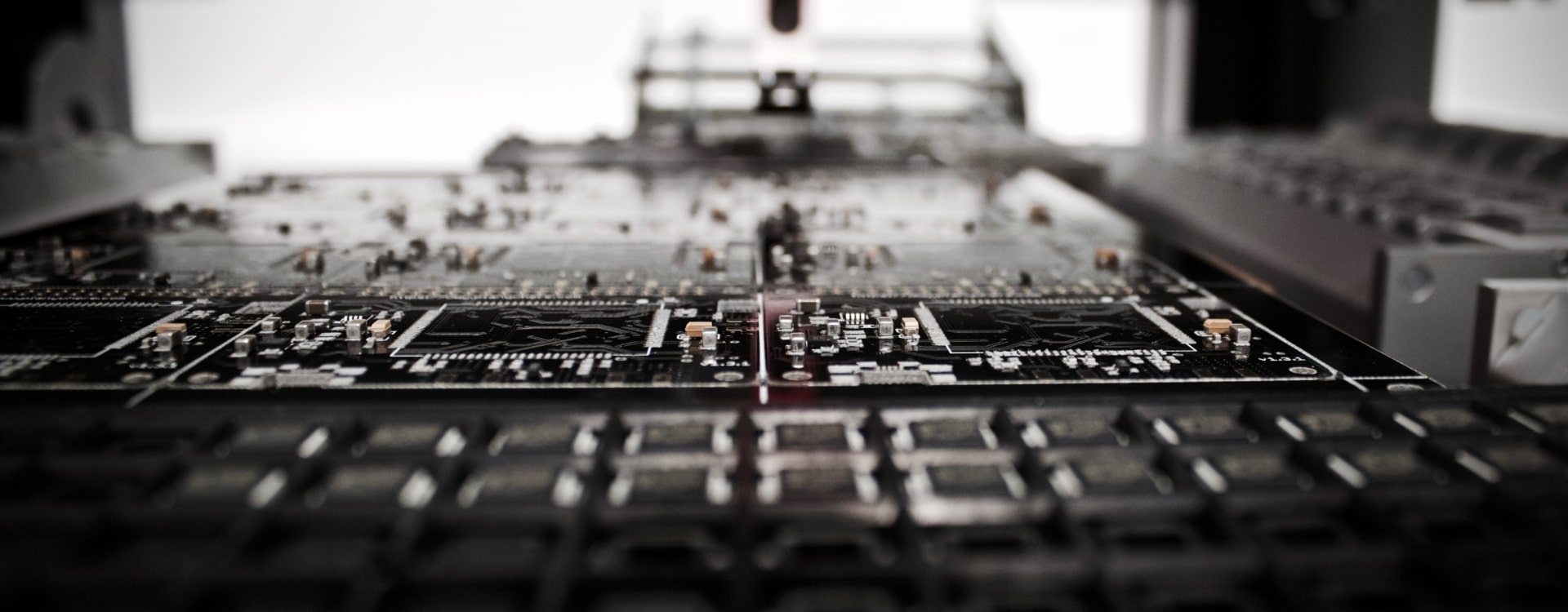

Concept models play a crucial role in the initial phases of product development, offering a tangible representation of new ideas and enhancements. They closely resemble finished products in terms of appearance, functionality, and even tactile experience. Concept models serve multiple purposes, such as gathering feedback from the market and users, showcasing at trade shows, and aiding in promotional material. These models are typically fabricated using a range of production processes that integrate various materials, including hard plastics, rubber-like components, transparent sections, buttons, numerical markings, graphics, logos, and more. Popular production methods for concept models encompass SLA (Stereolithography), SLS (Selective Laser Sintering), CJP (ColorJet Printing), PolyJet, Sheet Metal fabrication, and Cast Urethane parts. These techniques ensure a high level of accuracy and detail, allowing designers to visualize and communicate their ideas effectively in the early stages of product development. Concept models enable designers to refine and iterate their designs based on user feedback, resulting in improved product outcomes.

Concept modeling: Visualize ideas quickly with precise 3D printed models.

SLA concept models offer exceptional clarity and can be painted with automotive-grade paint, matching customer logos and branding standards.

SLS is ideal for durable and functional concept models, utilizing nylon-based powder for accurate and strong parts.

CJP prints vibrant full-color concept models without the need for secondary painting. Architectural models benefit greatly from this process.

PolyJet provides similar capabilities as SLA, with the added ability to print in multiple materials, making it suitable for complex concept models.

Cast Urethane concept models are versatile, functional, and durable. They feature texture, color matching, and options for inserts and pad printing of numbers, text, or logos.