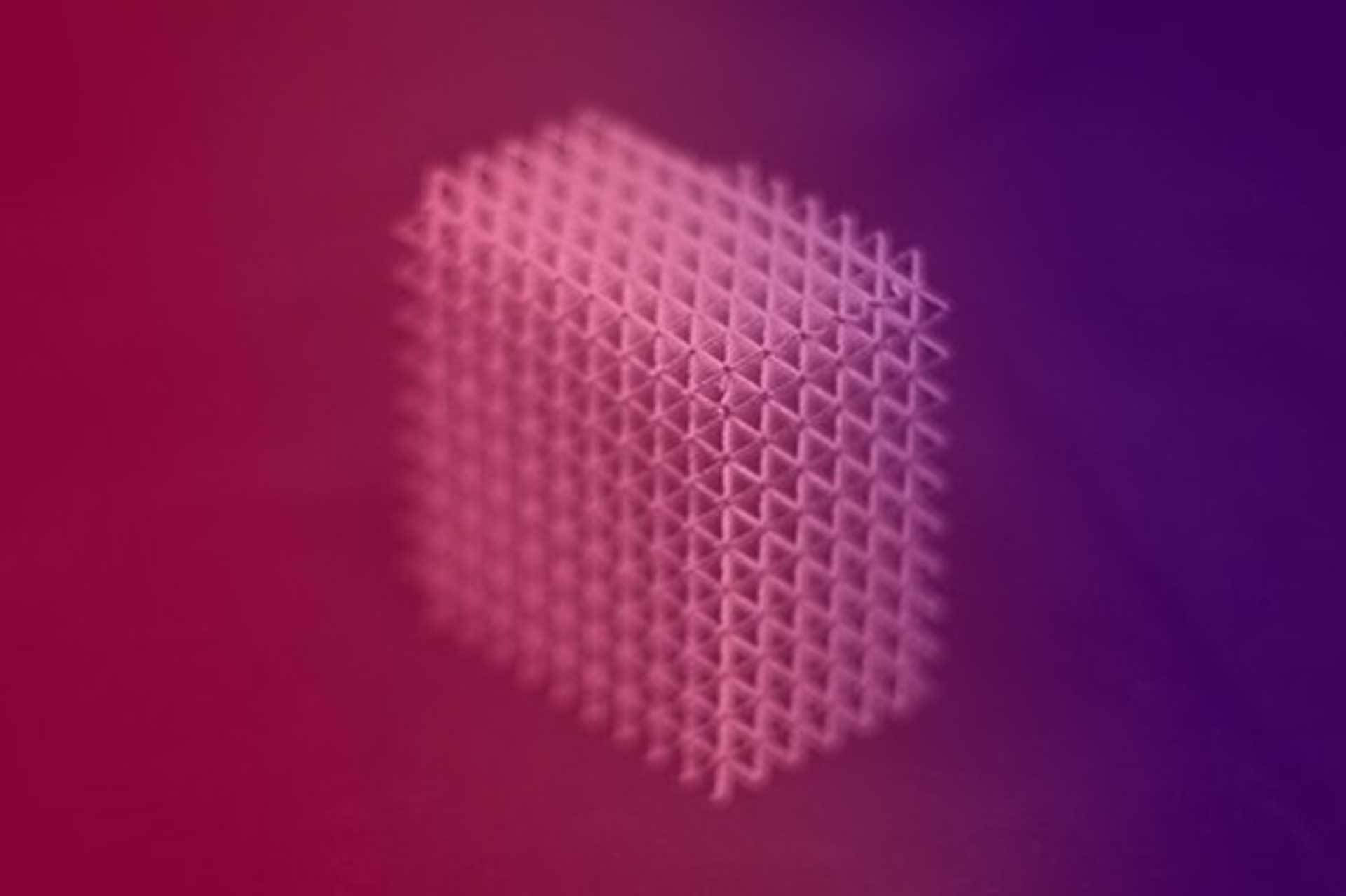

Direct Metal Laser Sintering (DMLS), also known as DMP (Direct Metal Printing), employs a high-wattage laser to precisely micro-weld powdered metals and alloys, enabling the creation of fully functional metal components directly from CAD data. It offers the advantage of eliminating tooling and enables the production of intricate geometries not feasible with other metal manufacturing methods. While Stainless Steel is the most commonly used material, options like Inconel, Aluminum, and Titanium are also available. DMLS parts exhibit strength, durability, and heat resistance, while being denser than investment cast metal parts. This precise metal 3D printing technique excels in producing fine feature detail, making it well-suited for complex oil and gas components, intricate small parts, custom medical guides, consolidated aerospace parts, and robust functional prototypes.

Direct Metal Laser Sintering: High-precision 3D printing technique for metal parts, fusing metal powders using a laser.

DMLS (Direct Metal Laser Sintering)

Direct Metal Laser Sintering: Precise 3D Metal Printing.

- Home

- 3D Printing

- DMLS (Direct Metal Laser Sintering)

DMLS revolutionizes manufacturing with rapid turnaround times for metal parts.

MINIMUM FEATURE SIZE

Range: .005” – .008”.

DENSITY

Range: 99.6% – 100%.

PLATFORM

Maximum single piece build size: 9.85” x 9.85” x 12.8”.

What we offer

IDEAL USES OF DMLS

➟ Tooling inserts

➟ Prototype parts

➟ End use metal components

➟ Multiple part consolidation

➟ Heat diffusers

➟ Conformal fluid channels

DMLS PRINTERS

➟ EOSINT M 280

➟ SLM 280

➟ ProX 300

➟ ProX 200

➟ enishaw AM 400

DMLS MATERIALS

Titanium

➟ EOS Titanium Ti64

➟ EOS Titanium Ti64ELI

Stainless Steel

➟ EOS Stainless Steel GP1

➟ EOS Stainless Steel PH1

➟ EOS Stainless Steel 316L

➟ EOS Stainless Steel CX (Corax)

Aluminum

➟ EOS Aluminum AISi10Mg

➟ CoCr

➟ EOS Cobalt Chrome MP1

➟ EOS Cobalt Chrome SP2

DMLS FINISHING OPTIONS

➟ Anodized

➟ EDM

➟ Grinding

➟ Heat Treated

➟ Milling

➟ Polished

➟ Turning

➟ Welding

Need more details?

We are here to assist. Contact us by phone, email or via our social media channels.