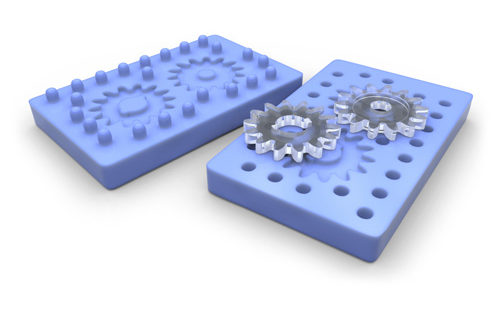

The cast urethane process efficiently produces low volumes of production urethane parts using silicone molds, offering a quick turnaround for molded parts with a diverse range of mechanical and thermal properties. With 3D printed and CNC quick-turn master patterns, fast curing silicone molds, and first shots within 7-10 business days, it enables fast-to-market advantages compared to traditional injection molding. These customizable parts can feature various colors, textures, clarity, threaded inserts, and more, making it a cost-effective option for large or intricate designs. Our capabilities extend to casting both small and large parts, reaching sizes comparable to a standard car bumper, with a single-piece production size of up to 91″ x 40″ x 37″.

Cast Urethane: Durable, versatile material with excellent resistance to abrasion, chemicals, and impact.

Cast Urethane (Silicone Molding)

Durable, Versatile, and Resilient: Cast Urethane

- Home

- 3D Printing

- Cast Urethane (Silicone Molding)

Cast urethane offers rapid turnaround times for producing high-quality functional prototypes and end-use parts in various industries.

BENEFITS

Fast turnaround, low-volume production, versatile materials, customized properties, cost-effective for complex designs.

LEAD TIME

Cast urethane offers quick lead times, with first shots available within 7-10 business days, providing a fast-to-market advantage for your parts.

TOLERANCES

Cast urethane offers tight tolerances, typically ranging from +/- 0.005″ to +/- 0.015″, ensuring precision and accuracy in produced parts.

BUILD LAYER THICKNESS

Versatile build layer thickness ensures precise detailing and production of functional parts with exceptional quality. Sizes up to 91″ x 40″ x 37″.

RECOMMENDED MINIMUM FEATURE SIZE

Recommended minimum feature size for cast urethane: .010″ – .020″. Achieve intricate details and precision in your urethane parts.

What we offer

IDEAL USES OF CAST URETHANE

➟ Production of a limited quantity of top-notch prototypes.

➟ Facilitation of engineering testing.

➟ Creation of focus group mock-ups and visual reviews.

➟ Provision of proof-of-concept and display demos.

➟ Utilization of precise production-like materials.

➟ Enablement of multiple design comparisons.

➟ Ability to over mold various materials and textures in a single part.

CAST URETHANE MATERIALS

➟ General Purpose ABS Like

➟ General Purpose PP Like

➟ Acetal Like

➟ Waterclear PC Like

➟ Rigid PA POM Like

➟ Elastomer Shore 30A

➟ Elastomer Shore 45A

➟ Elastomer Shore 55A

➟ Elastomer Shore 70A

➟ Elastomer Shore 83A

➟ High Temp ABS Like (120c)

➟ Ultra High Temp ABS Like (200c)

➟ ABS Like Food Grade

➟ Clear Rubber Like Food Grade

CAST URETHANE FINISHING OPTIONS

➟ Dip Coated

➟ EMI/RF Shielding

➟ Lacquer

➟ Light Pipe

➟ Light, Medium & Heavy Textures

➟ Nickel Plated

➟ Painted

Need more details?

We are here to assist. Contact us by phone, email or via our social media channels.