Our global growth is driven by innovations, successful projects and customers’ trust.

Modern 3D technologies

What we offer

SLA(STEREOLITHOGRAPHY)

Solidifying and hardening thin layers of a photosensitive resin, Stereolithography (SLA) enables the direct production of components from 3D CAD data.

MJF (Multi Jet Fusion)

Multi Jet Fusion rapidly construct functional plastic parts by fusing powdered Nylon thermoplastic material layer by layer, setting new records for speed and efficiency.

CAST URETHANE (SILICONE MOLDING)

The cast urethane process utilizes silicone molds to produce low-volume production plastic parts, making it perfect for functional molded components.

SLS(SELECTIVE LASER SINTERING)

Selective Laser Sintering (SLS) employs advanced CO2 laser technology to fuse thermoplastics, resulting in durable and intricately designed components.

POLYJET

Utilizing liquid photopolymers deposited layer by layer and cured with UV light, PolyJet is an additive process that achieves exceptional precision and detail.

CNC MACHINING

CNC machining subtractively manufactures parts by precisely cutting material using computer-controlled cutters, transforming blocks or sheets of stock material.

SHEET METAL

Transforming flat metal blanks into end-use parts, our cutting-edge manufacturing process combines water jet or laser cutting with precise tooling and forming techniques.

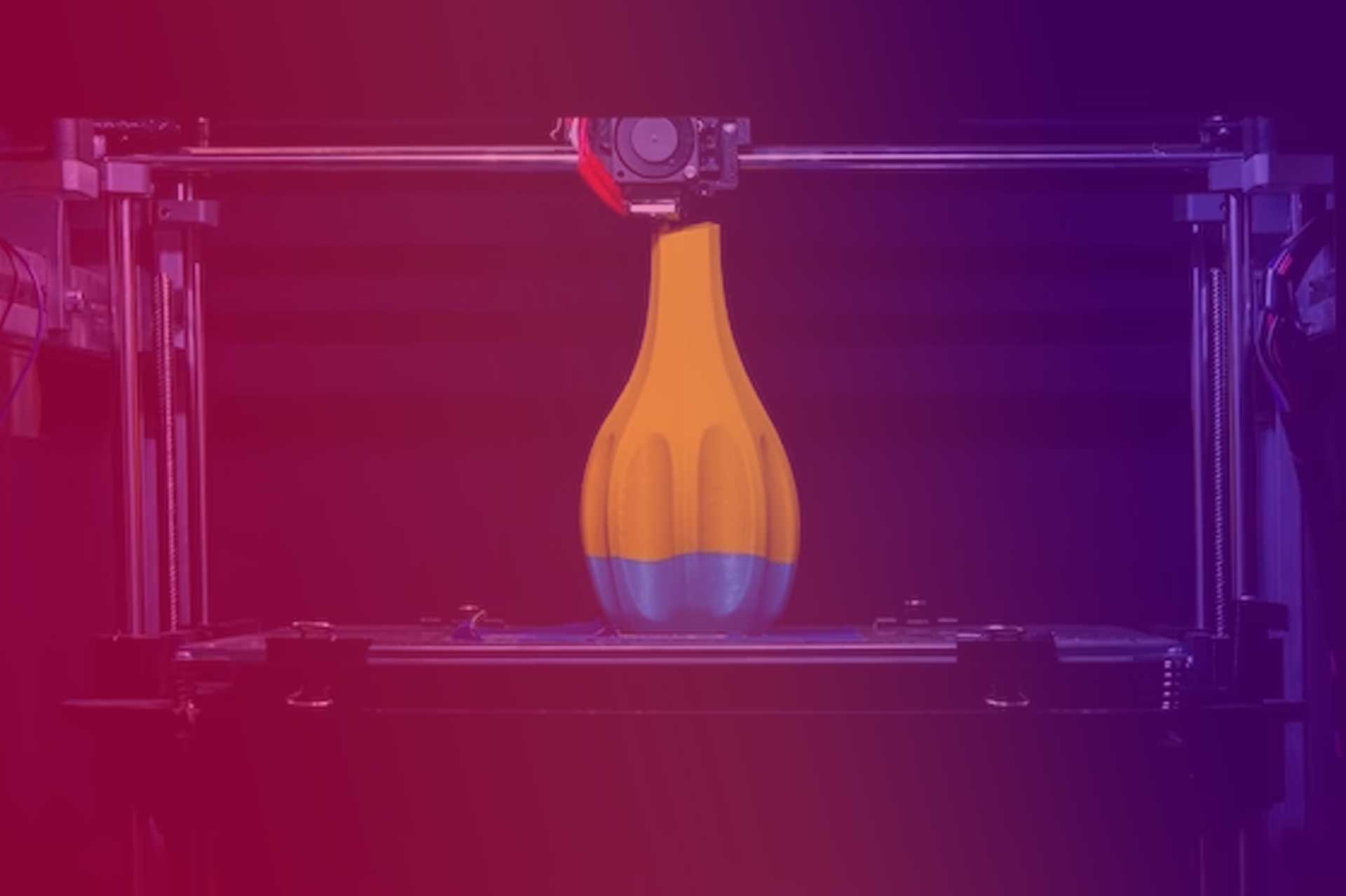

FDM (FUSED DEPOSITION MODELING)

FDM is a cutting-edge additive manufacturing technique that constructs parts by precisely melting and extruding thermoplastic filament through a nozzle, layer by layer.

DMLS (DIRECT METAL LASER SINTERING)

DMLS achieves exceptional precision by micro-welding powdered metals and alloys, resulting in fully functional metal components of the highest quality.

INJECTION MOLDING

Injection Molding employs molten thermoplastics injected under pressure into a durable mold, enabling high-volume production of thousands of precise parts.